18 Years Factory Fiberglass Composite Board - 3242 Epoxy Glassfiber Laminated Sheet – Xinxing

18 Years Factory Fiberglass Composite Board - 3242 Epoxy Glassfiber Laminated Sheet – Xinxing Detail:

Product Description

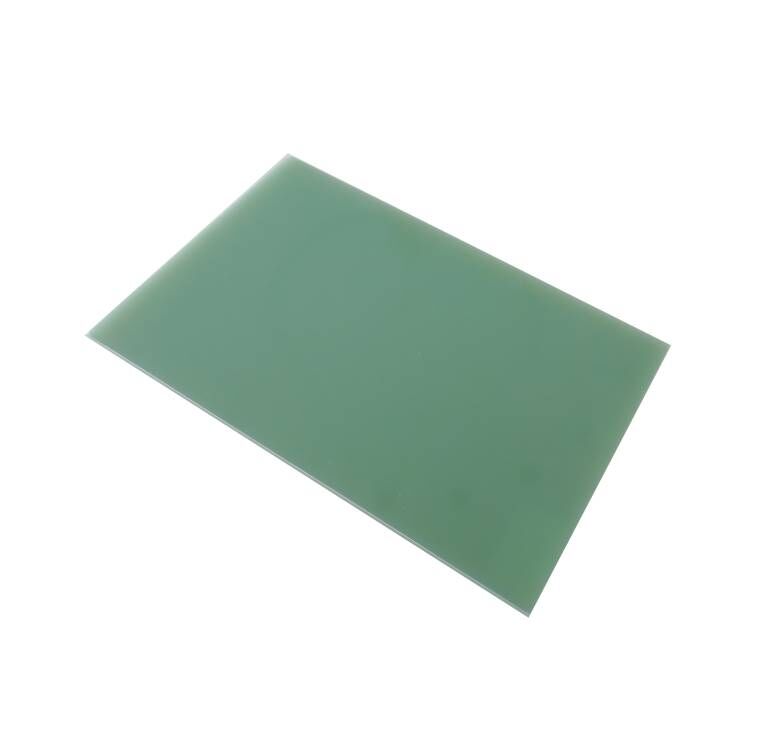

This product is a laminated product which made with the chemical treatment electrical purposed alkali-free glass cloth as the backing material,by hot pressing with epoxy resin as binder.It has high mechanical strength under high temperature,with good electrical stability under high humidity.The thermostability is grade F,suitable for all kinds of motor, electric appliances,electronic and other fields.

Features

1.Good electrical stability under high humidity;

2.High mechanical strength under high temperature;

3.Moisture resistance;

4.Heat resistance;

5.Temperature resistance:Grade F

Compliance With Standards

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates – Part 4: epoxy resin hard laminates.

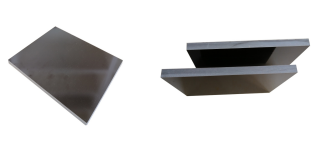

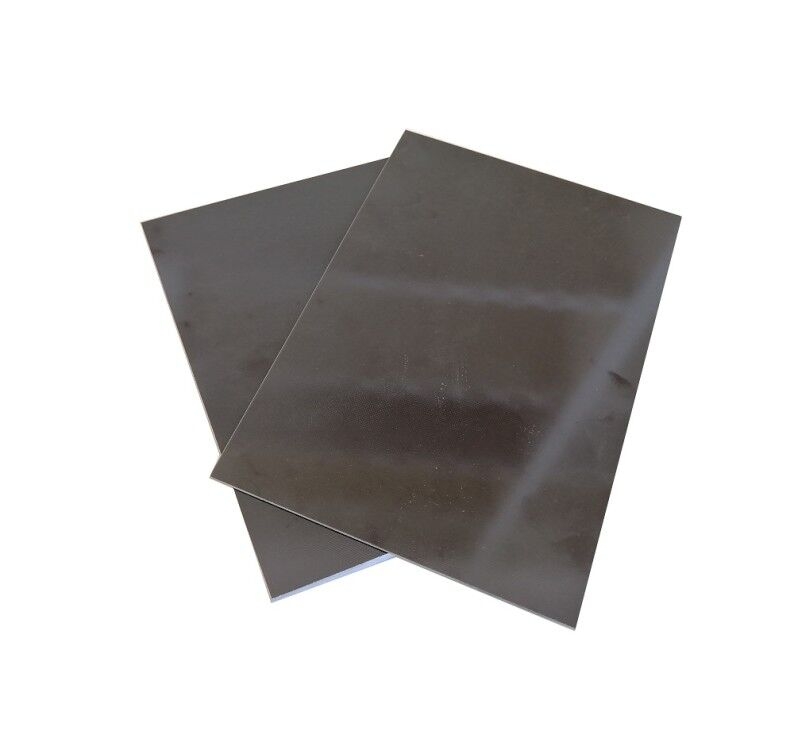

Appearance: the surface should be flat, free of bubbles, pits and wrinkles, but other defects that do not affect the use are allowed, such as: scratches, indentation, stains and a few spots.The edge shall be cut neatly, and the end face shall not be delaminated and cracked.

Application

Suitable for all kinds of motor, electric appliances,electronic and other fields.

Main Performance Index

| NO. | ITEM | UNIT | INDEX VALUE | ||

| 1 | Density | g/cm³ | 1.8-2.0 | ||

| 2 | Water absorption Rate | % | ≤0.5 | ||

| 3 | Vertical bending strength | Normal | MPa | ≥340 | |

| 155±2℃ | ≥170 | ||||

| 4 | Compression strength | Vertical | MPa | ≥300 | |

| Parallel | ≥200 | ||||

| 5 | Impact strength (charpy type-gap) | Lengthway no gap | KJ/m² | ≥147 | |

| Horizontal no gap | ≥98 | ||||

| 6 | Bonding strength | N | ≥6800 | ||

| 7 | Tensile strength | Lengthway | MPa | ≥280 | |

| Horizontal | ≥200 | ||||

| 8 | Vertical electric strength (in oil of 90℃±2℃) |

1mm | KV/mm | ≥14.2 | |

| 2mm | ≥11.8 | ||||

| 3mm | ≥10.2 | ||||

| 9 | Parallel breakdown voltage(1 min in oil of 90℃±2℃) | KV | ≥35 | ||

| 10 | Dielectric dissiption factor(50Hz) | - | ≤0.04 | ||

| 11 | Parrallel Insulation Resistance | Normal | Ω | ≥1.0×1012 | |

| After soaking for 24hours | ≥1.0×1010 | ||||

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for 18 Years Factory Fiberglass Composite Board - 3242 Epoxy Glassfiber Laminated Sheet – Xinxing, The product will supply to all over the world, such as: Ukraine, Luxembourg, Czech, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.