3242 Epoxy Fiberglass Laminated Sheet(High strength G11)

Product Instruction

This product is made with the electrician non-alkali glass fiber cloth as the backing material, with high TG epoxy resin as binder via hot pressing laminated under 155 degree temperature.It has high mechanical strength under normal temperature , still has strong mechanical strength , good electrical properties under dry and wet environment, can be used in damp environment and transformer oil.It belongs to grade F heat resistance insulating material.The technical data is similar to G11,but improved the mechanical strength.

Compliance with standards

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates - Part 4: epoxy resin hard laminates, IEC 60893-3-2-2011 insulating materials - electrical thermosetting resin industrial hard laminates - Part 3-2 of the individual material specification EPGC203.

Application

Applicable to all kinds of motor, electrical, electronic and other fields, widely used in motor, electrical equipment as insulation structure parts, high voltage switchgear, high voltage switch (such as motor stator insulation materials at both ends, rotor end plate rotor flange piece, slot wedge, wiring plate, etc.).

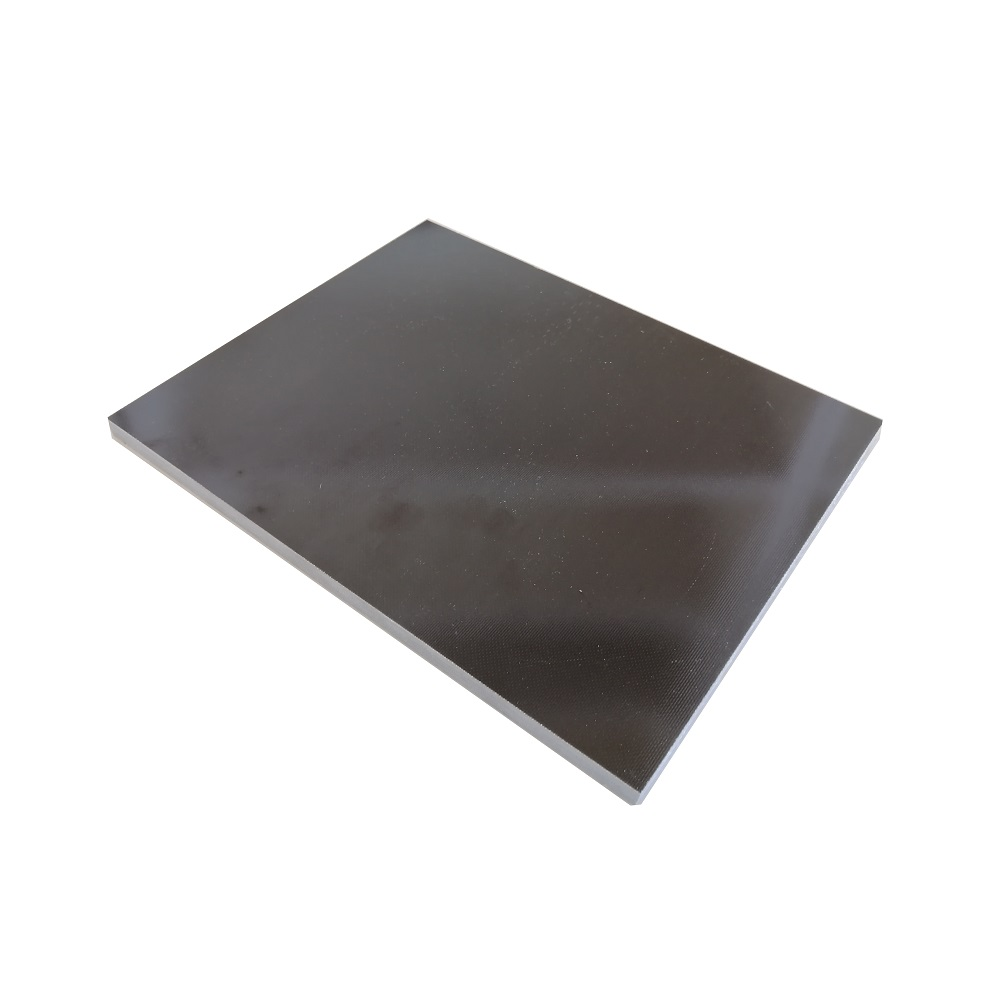

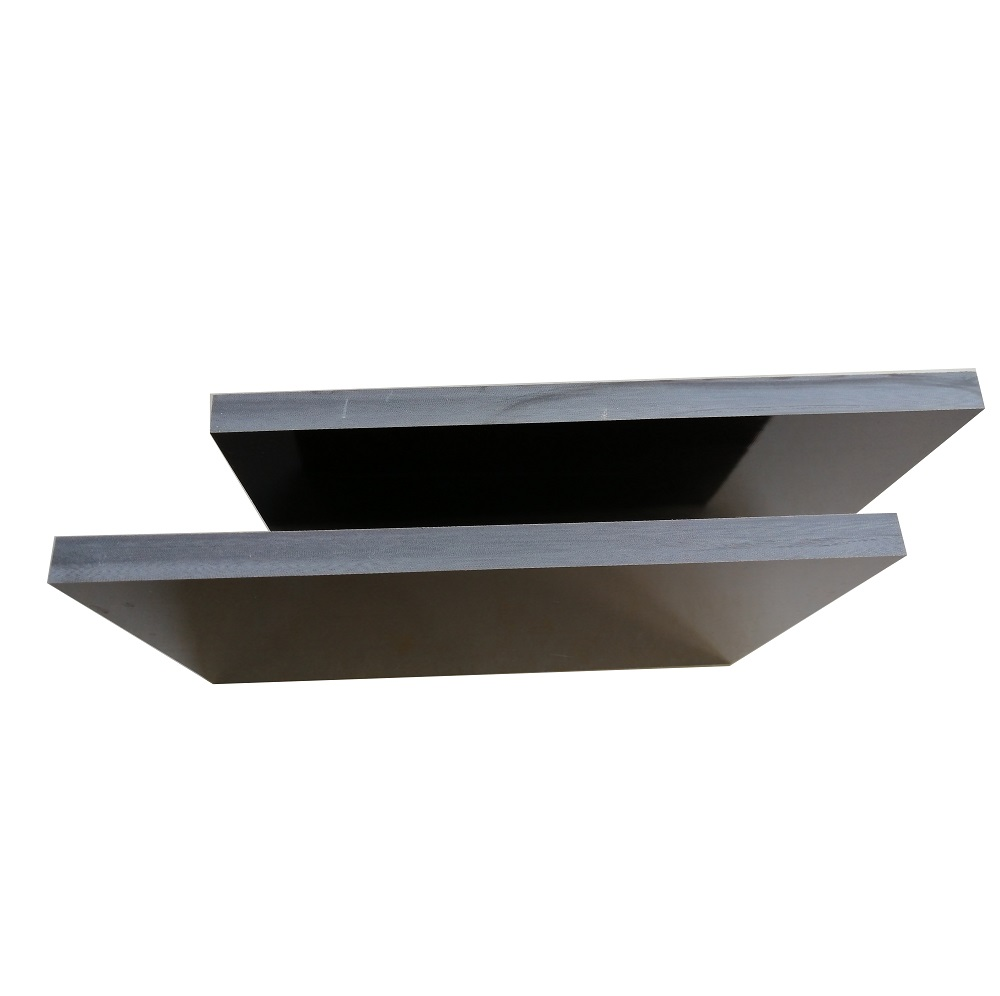

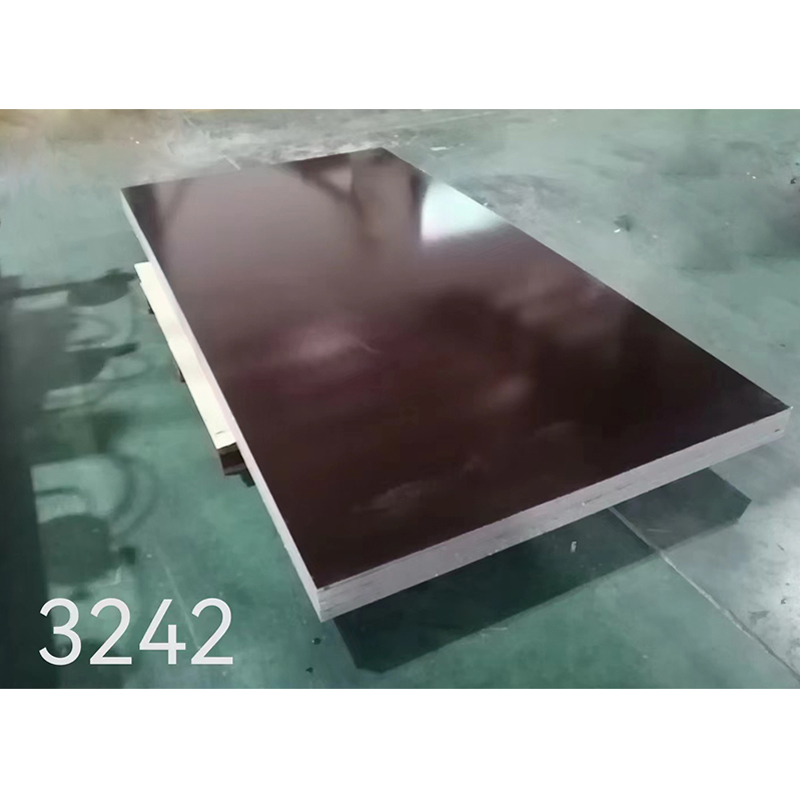

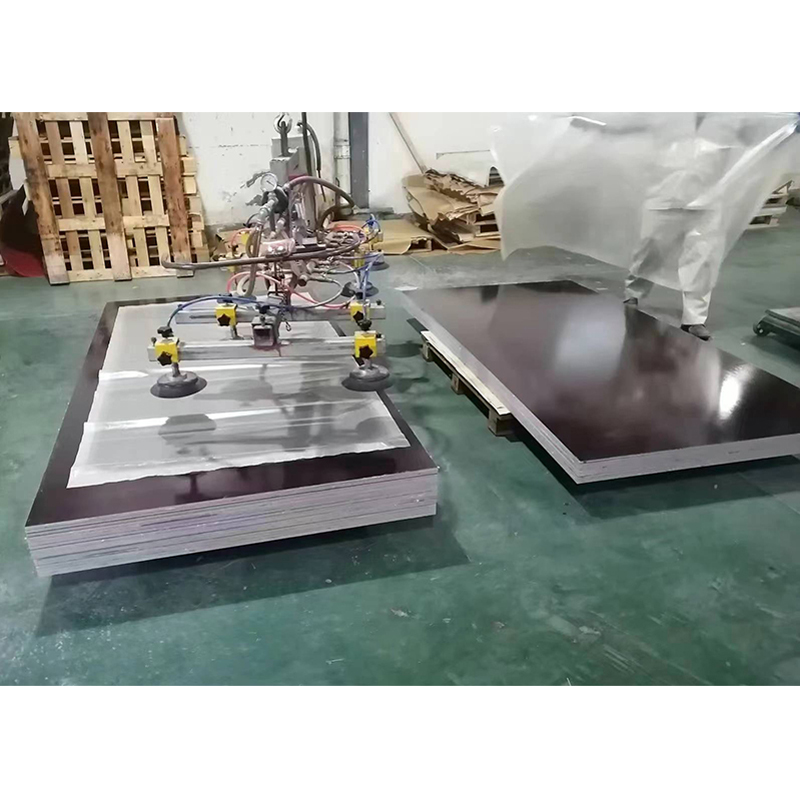

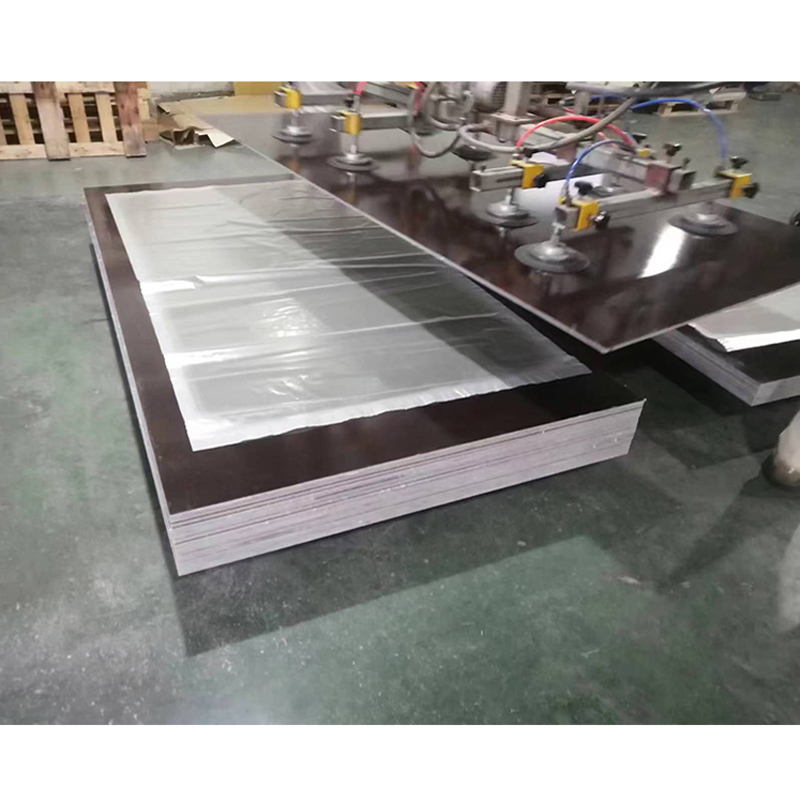

Product pictures

Main Technical Date(Click here to download the third party test report)

|

Item |

Property |

Unit |

Standard Value |

Typical Value |

Test Method |

|

1 |

Flexural strength perpendicular to laminations |

MPa |

≥380 |

639 |

GB/T 1303.2 |

|

2 |

Flexural strength perpendicular to laminations |

MPa |

≥190 |

432 |

|

|

3 |

Tensile strength |

MPa |

≥300 |

460 |

|

|

4 |

Charpy impact strength parallel to laminations (Notched) |

kJ/m2 |

≥33 |

105 |

|

|

5 |

Electric strength perpendicular to laminations (at 90℃±2℃ in oil ),1mm in thickness |

kV/mm |

≥14.2 |

21.9 |

|

|

6 |

Breakdown voltage parallel to laminations(at 90℃±2℃ in oil) |

kV |

≥35 |

≥100 |

|

|

7 |

Insulation resistance(after 24h immersion in water) |

MΩ |

≥5.0×104 |

8.0×108 |

|

|

8 |

Relative Permittivity(50Hz) |

- |

≤5.5 |

4.87 |

|

|

9 |

Water absorption,3mm in thickness |

mg |

≤22 |

17 |

|

|

10 |

Comparative tracking index(CTI) |

_ |

_ |

CTI600 |

|

|

11 |

Density |

g/cm3 |

1.80~2.0 |

1.85 |

|

|

12 |

Adhesion strength |

N |

_ |

8053 |

|

|

13 |

TG (DSC) |

℃ |

_ |

175℃ |

FAQ

Q1: Are you trading company or manufacturer?

We are the leading manufacturer of electrical insulating composite,We have been engaged in manufacturer thermoset rigid composite since 2003.Our capacity is 6000TONS/year.

Q2: Samples

Samples are free,you only need to pay for the shipping charge.

Q3: How do you guarantee the quality of mass production?

For appearance,size and thickness: we will make full inspection before packing.

For performance quality: We use a fixed formula, and will be regular sampling inspection, we can provide product inspection report before shipment.

Q4: Delivery time

It depends on order quantity.Generally speaking, the delivery time will be 15-20 days.

Q5: Package

We will use professional craft paper to package on plywood pallet.if you have special package requirements, we will pack as your need.

Q6: Payment

TT, 30% T/T in advance ,balance before shipment.We also accept L/C.