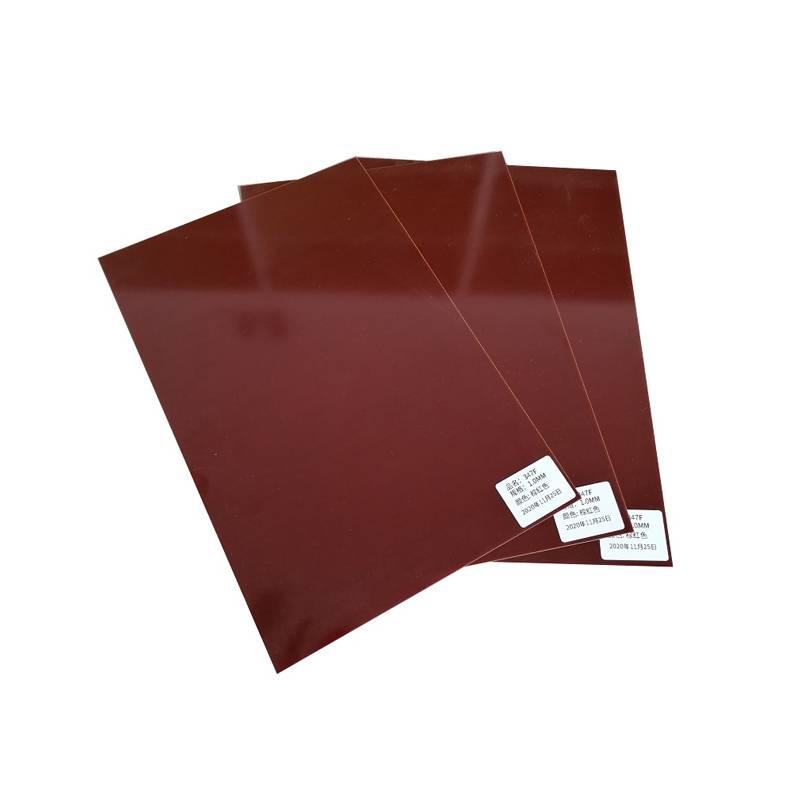

347/347F High Strength Epoxy Glassfiber laminated sheet (Thermostability is grade F)

Product Description

This product is a laminated sheet which made with processed non-alkali glass fiber cloth as the backing material, by hot pressing with grade F benzo oxazine resin. It has good mechanical and electrical properties,and flame retardant, especially has high mechanical strength retention and excellent electrical properties under high temperature.Suitable for grade F motor and electrical equipment as high quality insulation structure , has the advantage of good machinability and wide applicability in the similar products.

Features

1.Good mechanical and electrical properties;

2.High mechanical strength retention and

excellent electrical properties under high temperature;

3.Moisture resistance;

4.Heat resistance;

5.Temperature resistance:Grade F;

6.Good Machinability and wide applicability

7.Flame retardant property:UL94 V-0

Compliance With Standards

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates - Part 4: epoxy resin hard laminates.

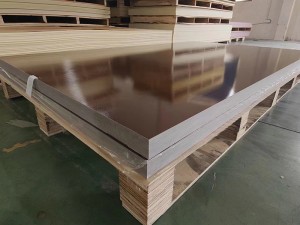

Appareance: the surface should be flat, free of bubbles, pits and wrinkles, but other defects that do not affect the use are allowed, such as: scratches, indentation, stains and a few spots.The edge shall be cut neatly, and the end face shall not be delaminated and cracked.

Application

The technical data of 347F is similar to FR5,Suitable for grade F motor and electrical equipment as high quality insulation structure.

Main Performance Index

| NO. | ITEM | UNIT | INDEX VALUE | |||

| 347 | 347F | |||||

| 1 | Density | g/cm³ | 1.8-2.0 | 1.8-2.0 | ||

| 2 | Water absorption Rate | % | ≤0.5 | ≤0.5 | ||

| 3 | Vertical bending strength | Normal | MPa | ≥440 | ≥400 | |

| 155±2℃ | ≥280 | ≥250 | ||||

| 4 | Compression strength | Vertical | MPa | ≥350 | ≥300 | |

| Parallel | ≥260 | ≥200 | ||||

| 5 | Impact strength (charpy type) | Lengthway no gap | KJ/m² | ≥147 | ≥129 | |

| Horizontal no gap | ≥98 | ≥77 | ||||

| 6 | Bonding strength | N | ≥7200 | ≥6800 | ||

| 7 | Tensile strength | Lengthway | MPa | ≥280 | ≥240 | |

| Horizontal | ≥200 | ≥180 | ||||

| 8 | Vertical electric strength (in oil of 90℃±2℃) |

1mm | KV/mm | ≥14.2 | ≥14.2 | |

| 2mm | ≥12.4 | ≥12.4 | ||||

| 3mm | ≥11.5 | ≥11.5 | ||||

| 9 | Parallel breakdown voltage(1 min in oil of 90℃±2℃) | KV | ≥45 | ≥45 | ||

| 10 | Dielectric dissiption factor(50Hz) | - | ≤0.04 | ≤0.04 | ||

| 11 | Volumn Insulation Resistance | Normal | Ω | ≥1.0×1012 | ≥1.0×1012 | |

| After soaking for 24hours | ≥1.0×1010 | ≥1.0×1010 | ||||

| 12 | Combustibility(UL-94) | Level | V-1 | V-0 | ||