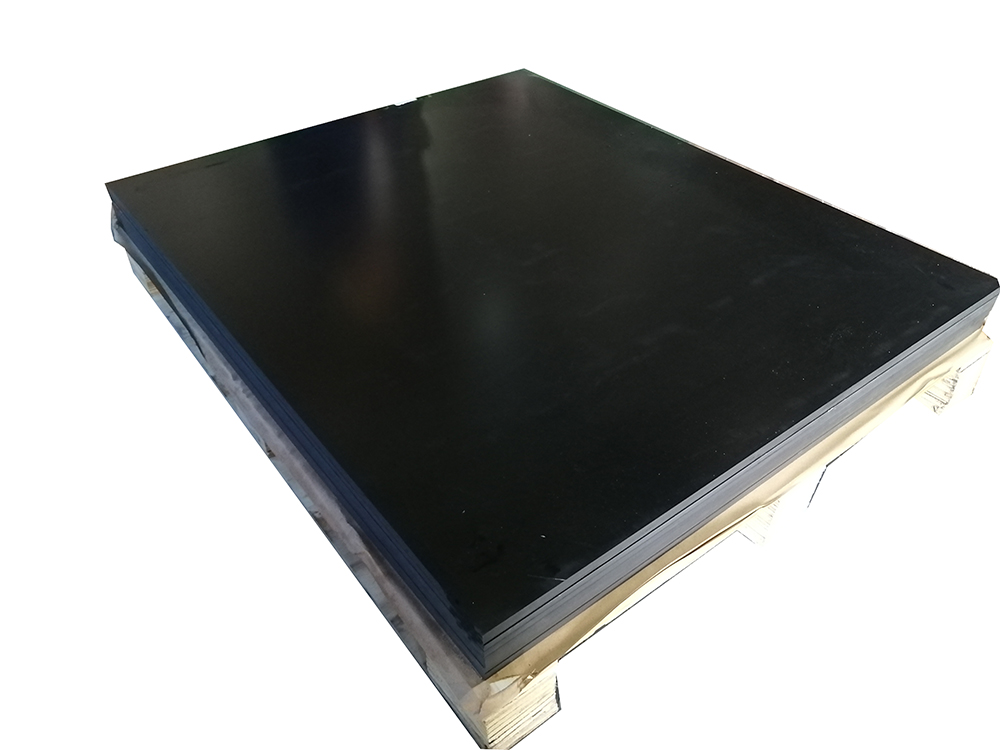

China factory G10 ESD Anti-Static Epoxy Glassfiber Laminated Sheet

Product Description

This product is a laminated product made from non-alkali glass cloth dipped in epoxy resin by hot pressing. It has anti-static (anti-static) characteristics and good mechanical processing performance. The anti-static plate can be divided into three types: full anti-static plate, single-sided anti-static plate and double-sided anti-static plate.Suitable for electronic and electrical industries.

Features

1.Anti-static properties;

2.Good mechanical properties;

3.Moisture resistance;

4.Heat resistance;

5.Temperature resistance:Grade B

Compliance With Standards

Appareance: the surface should be flat, free of bubbles, pits and wrinkles, but other defects that do not affect the use are allowed, such as: scratches, indentation, stains and a few spots.The edge shall be cut neatly, and the end face shall not be delaminated and cracked.

Application

Appy to electronic,electrical and other industries,can be used as anti-static hollow plate for current isolation and service for various test smelter manufacturers, ICT test smelter manufacturers, ATE vacuum smelter manufacturers, functional smelter manufacturers and various electronic and motherboard manufacturers.

Main Performance Index

| NO. | ITEM | UNIT | INDEX VALUE | ||

| 1 | Density | g/cm³ | 1.8-2.0 | ||

| 2 | Water absorption Rate | % | <0.5 | ||

| 3 | Vertical bending strength | MPa | ≥350 | ||

| 4 | Vertical compression strength | MPa | ≥350 | ||

| 5 | Parallel impact strength (charpy type-gap) | KJ/m² | ≥33 | ||

| 6 | Tensile strength | MPa | ≥240 | ||

| 7 | Surface Insulation Resistance | Ω | 1.0×106~1.0×109 | ||