Factory wholesale Electrical Insulation Supply - Grade F Halogen-free fire retardant Epoxy glass fiber laminated sheet – Xinxing

Factory wholesale Electrical Insulation Supply - Grade F Halogen-free fire retardant Epoxy glass fiber laminated sheet – Xinxing Detail:

Product Description

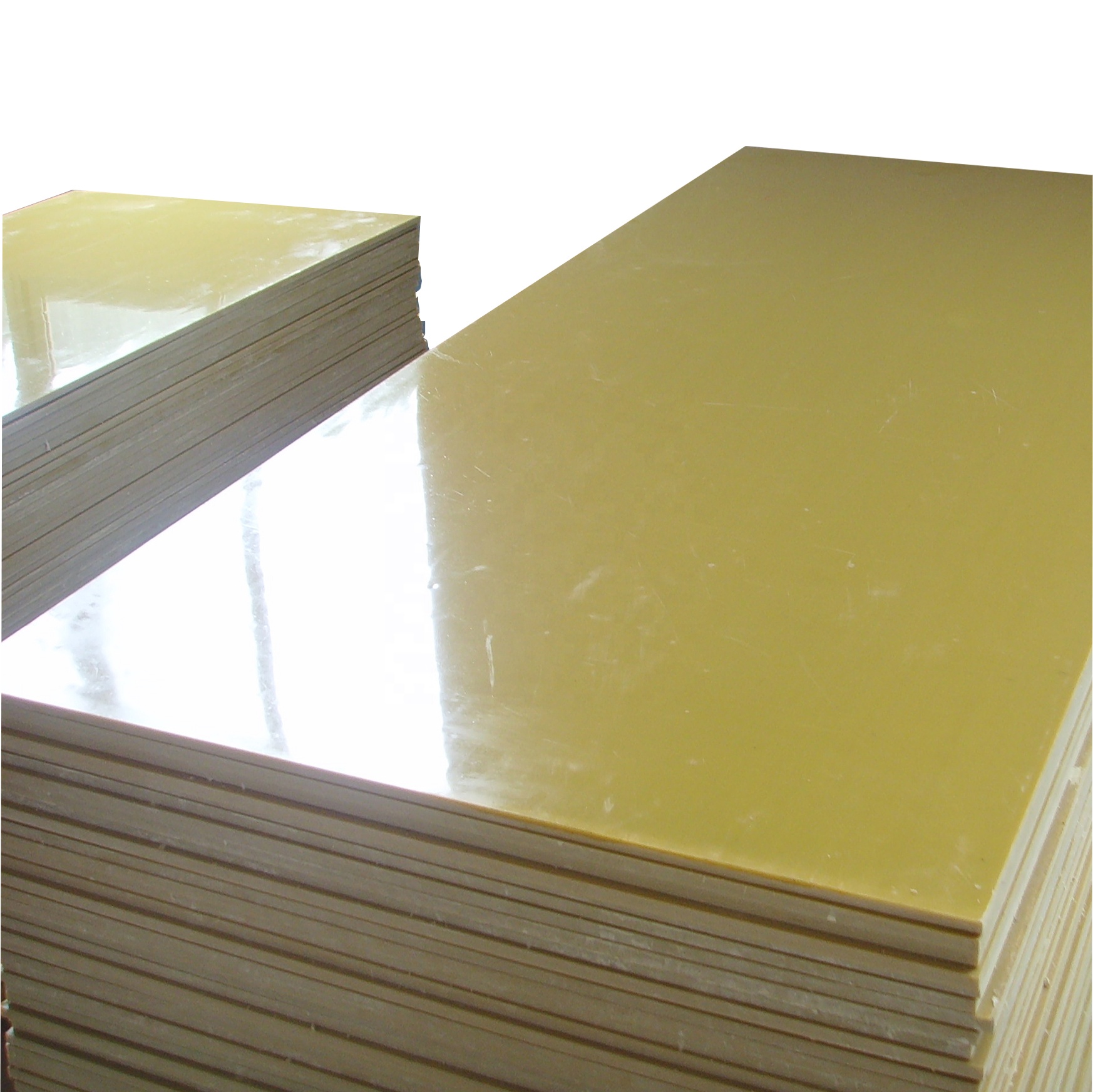

This product is made with the electrician non-alkali glass fiber cloth as the backing material, with high TG phosphorous and nitrogen flame retardant epoxy resin as binder via hot pressing laminated products, high mechanical strength and low combustion performance under normal temperature, high temperature under 155 ℃ still has strong mechanical strength, good electrical properties under dry and wet state, can be used in damp environment and transformer oil,It is a class F heat-resistant insulating material.Applicable to all kinds of motor, electrical, electronic and other fields, widely used in motor, electrical equipment as insulation structure parts, high voltage switch-gear, high voltage switch (such as motor stator insulation materials at both ends, rotor end plate rotor insulation piece, slot wedge, terminal board, etc.).

Features

1.Good electrical stability under high humidity;

2.High mechanical strength under high temperature;

3.Moisture resistance;

4.Heat resistance;

5.Temperature resistance:Grade F

6.Halogen-free and fire retardant

Compliance with standards

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates – Part 4: epoxy resin hard laminates.

Appearance: the surface should be flat, free of bubbles, pits and wrinkles, but other defects that do not affect the use are allowed, such as: scratches, indentation, stains and a few spots.The edge shall be cut neatly, and the end face shall not be delaminated and cracked.

Compliance with standards

Suitable for all kinds of motor, electric appliances,electronic and other fields.

Main Performance Index

| NO. | ITEM | UNIT | INDEX VALUE | ||

| 1 | Density | g/cm³ | 1.8-2.0 | ||

| 2 | Water absorption Rate | % | ≤0.5 | ||

| 3 | Vertical bending strength | Normal | MPa | ≥380 | |

| 155±2℃ | ≥190 | ||||

| 4 | Compression strength | Vertical | MPa | ≥300 | |

| Parallel | ≥200 | ||||

| 5 | Impact strength (charpy type) | Lengthway no gap | KJ/m² | ≥147 | |

| 6 | Bonding strength | N | ≥6800 | ||

| 7 | Tensile strength | Lengthway | MPa | ≥300 | |

| Horizontal | ≥240 | ||||

| 8 | Vertical electric strength (in oil of 90℃±2℃) |

1mm | KV/mm | ≥14.2 | |

| 2mm | ≥11.8 | ||||

| 3mm | ≥10.2 | ||||

| 9 | Parallel breakdown voltage(1 min in oil of 90℃±2℃) | KV | ≥40 | ||

| 10 | Dielectric dissiption factor(50Hz) | - | ≤0.04 | ||

| 11 | Insulation Resistance | Normal | Ω | ≥1.0×1012 | |

| After soaking for 24hours | ≥1.0×1010 | ||||

| 12 | Combustibility(UL-94) | Level | V-0 | ||

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for Factory wholesale Electrical Insulation Supply - Grade F Halogen-free fire retardant Epoxy glass fiber laminated sheet – Xinxing, The product will supply to all over the world, such as: Angola, Mexico, Grenada, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We've been looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.