G11R Epoxy Fiberglass Laminated Sheet(EPGC205)

Product Instruction

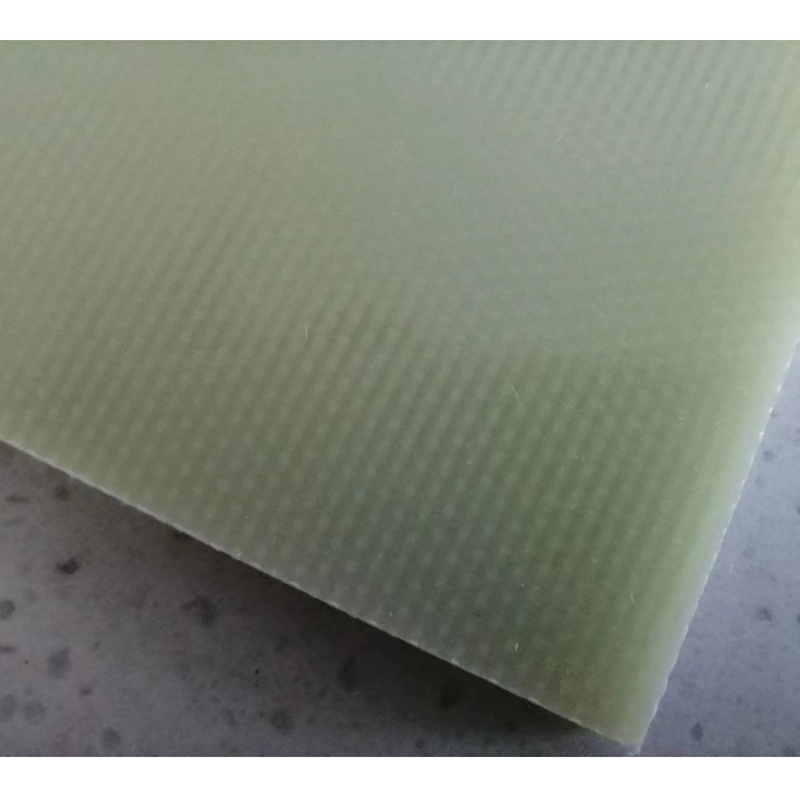

EPGC205/Roving reinforced G11R material are continuous filament woven fiberglass sheets bonded with high temperature epoxy resin. EPGC205/G11R is similar to type EPGC203/G11R,but with roving cloth.The material has the ability to maintain excellent mechanical,electrical and physical properties at elevated temperature to 155℃.

Compliance with standards

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates - Part 4: epoxy resin hard laminates, IEC 60893-3-2-2011 insulating materials - electrical thermosetting resin industrial hard laminates - Part 3-2 of the individual material specification EPGC205.

Application

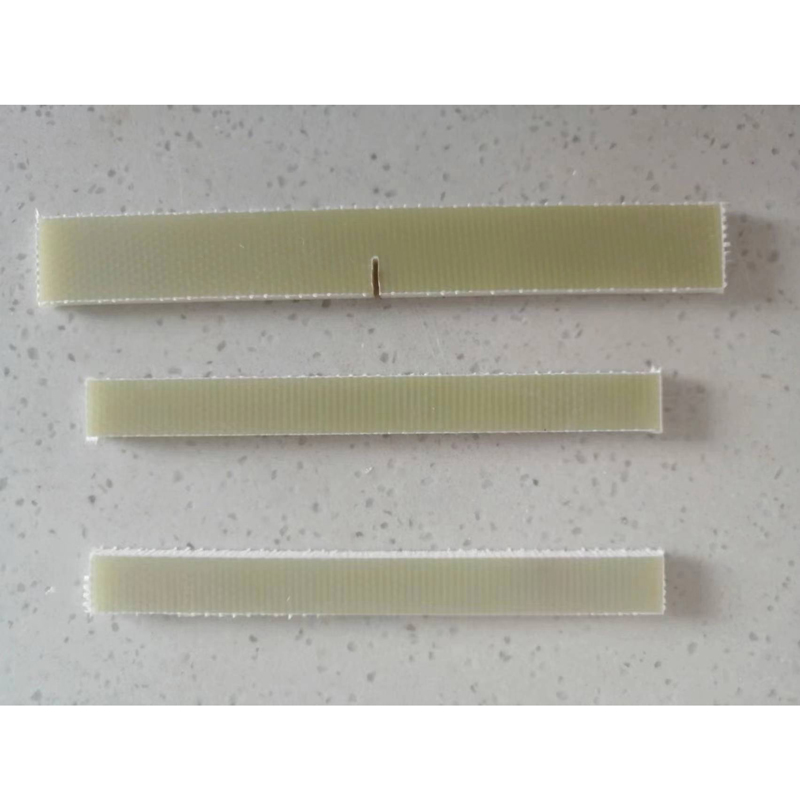

Mostly used in electrical machines and equipments as slot-wedges, fillers, cover plates, nut insulation, inter mediates, distances, etc.

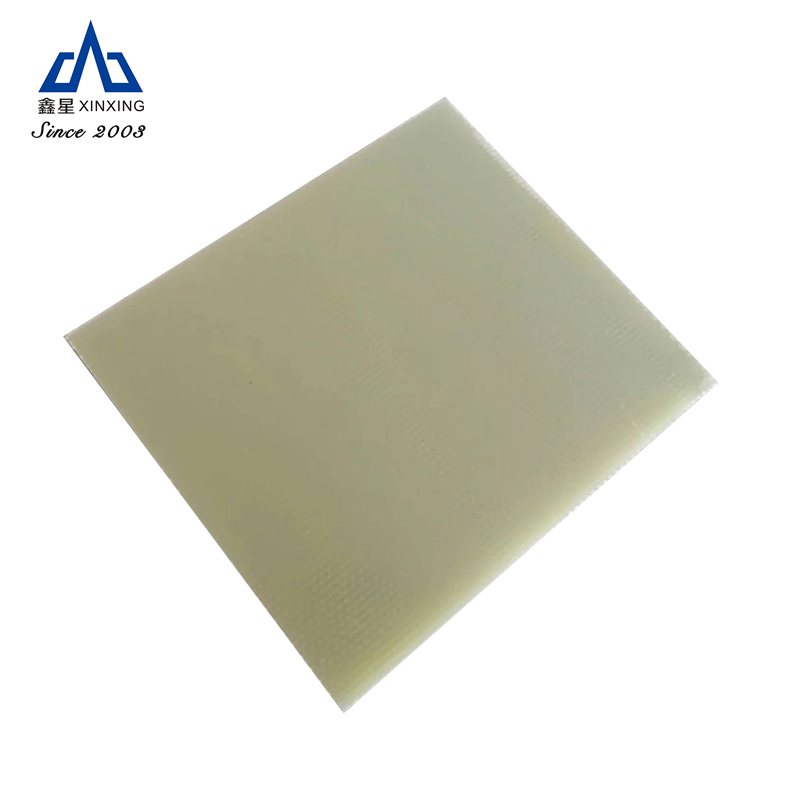

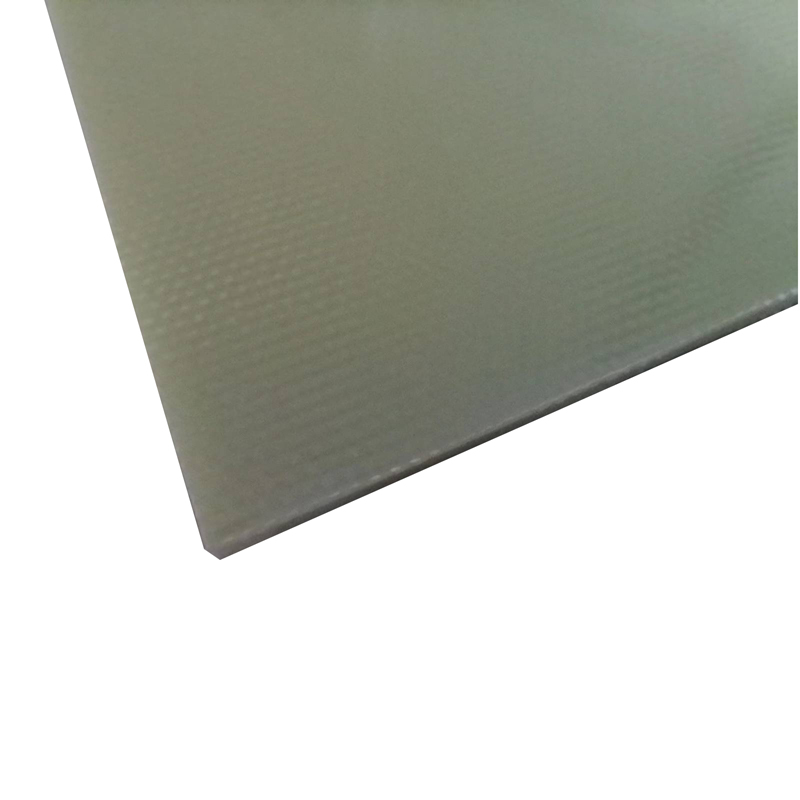

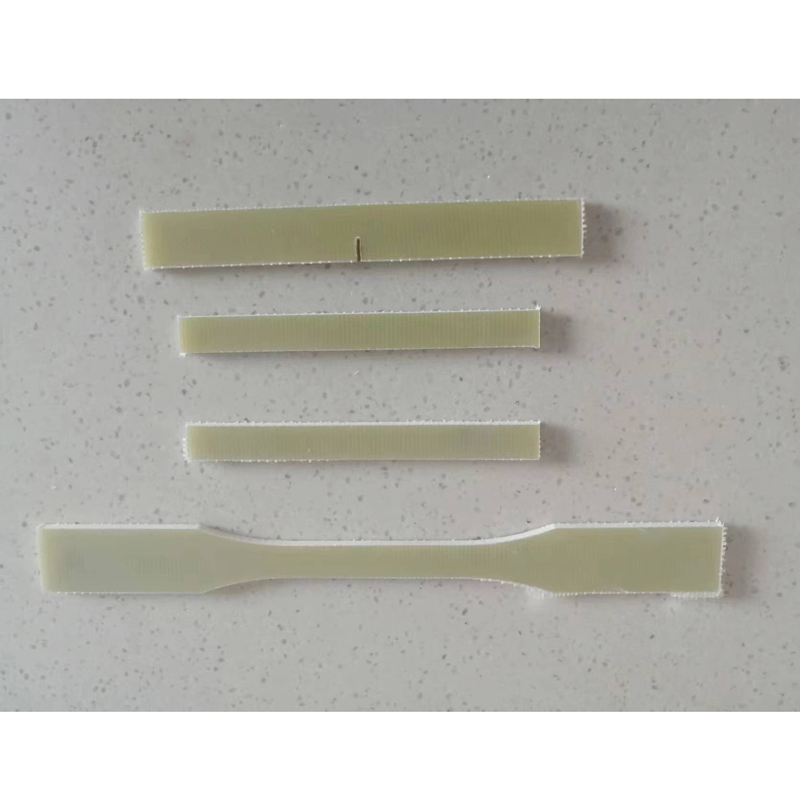

Product pictures

Main Technical Date(Click here to download the third party test report)

|

Item |

Property |

Unit |

Standard Value |

Typical Value |

Test Method |

|

1 |

Flexural strength perpendicular to laminations |

MPa |

≥340 |

510 |

GB/T 1303.2 |

|

2 |

Flexural strength perpendicular to laminations |

MPa |

≥170 |

320 |

|

|

3 |

Tensile strength |

MPa |

≥300 |

530 |

|

|

4 |

Charpy impact strength parallel to laminations (Notched) |

kJ/m2 |

≥70 |

170 |

|

|

5 |

Flexural modulus perpendicular to laminations(under normal condition) |

MPa |

-- |

3.2x104 |

|

|

6 |

Flexural modulus perpendicular to laminations(under 150±5℃) |

MPa |

-- |

3.0x104 |

|

|

7 |

Electric strength perpendicular to laminations (at 90℃±2℃ in oil ),3mm in thickness |

kV/mm |

≥9 |

20 |

|

|

8 |

Breakdown voltage parallel to laminations(at 90℃±2℃ in oil) |

kV |

≥45 |

≥50 |

|

|

9 |

Insulation resistance(after 24h immersion in water) |

MΩ |

≥1.0×104 |

3.8×105 |

|

|

10 |

Water absorption,3mm in thickness |

mg |

≤22 |

17 |

|

|

11 |

Comparative tracking index(CTI) |

_ |

_ |

CTI600 |

|

|

12 |

Density |

g/cm3 |

1.80~2.0 |

1.99 |

|

|

13 |

Temperature index |

℃ |

_ |

155℃ |

|

|

14 |

Flammability |

Class |

HB |

HB |

FAQ

Q1: Are you trading company or manufacturer?

We are the leading manufacturer of electrical insulating composite,We have been engaged in manufacturer thermoset rigid composite since 2003.Our capacity is 6000TONS/year.

Q2: Samples

Samples are free,you only need to pay for the shipping charge.

Q3: How do you guarantee the quality of mass production?

For appearance,size and thickness: we will make full inspection before packing.

For performance quality: We use a fixed formula, and will be regular sampling inspection, we can provide product inspection report before shipment.

Q4: Delivery time

It depends on order quantity.Generally speaking, the delivery time will be 15-20 days.

Q5: Package

We will use professional craft paper to package on plywood pallet.if you have special package requirements, we will pack as your need.

Q6: Payment

TT, 30% T/T in advance ,balance before shipment.We also accept L/C.