Manufacturing Companies for Fiber Glass Board - FR4 Rigid Epoxy Glassfiber Laminated Sheet – Xinxing

Manufacturing Companies for Fiber Glass Board - FR4 Rigid Epoxy Glassfiber Laminated Sheet – Xinxing Detail:

Product Description

This product was laminated by the high temperature and high pressure with electronic glassfiber cloth impregnated with brominated epoxy resin.It with high mechanical properties,dielectric properties and flame retardant properties,it also with good heat resistance and moisture resistance;

FR-4 is a code of a grade of flame-resistant materials, which means a material specification that a resin material must be able to extinguish by itself after burning. It is not a material name, but a material grade. The name FR4 comes from the NEMA grading system where the ‘FR’ stands for ‘fire retardant’, compliant with the UL94V-0 standard. Therefore, general PCB circuit boards, There are many types of FR-4 grade materials used, but most of them are composite materials made of Tera-Function epoxy resin with filler and glass fiber.

Compliance With Standards

In accordance with GB/T 1303.4-2009 electrical thermosetting resin industrial hard laminates – Part 4: epoxy resin hard laminates, IEC 60893-3-2-2011 insulating materials – electrical thermosetting resin industrial hard laminates – Part 3-2 of the individual material specification EPGC202.

Features

1.High mechanical properties;

2.High dielectric properties;

3.Good Mechinability

4.Good moisture resistance;

5.Good heat resistance;

6.Temperature resistance:Grade B,130℃

7.Flame retardant property:UL94 V-0

Application

This product is mainly used as the structure parts for Motor and electrical equipment,including all kinds of switch, electric equipment, FPC reinforcement plate, carbon film printed circuit boards, computer drilling pad, mould and smelting equipment(PCB test flame);and also suitable under wet environment and transformer oil.

Main Performance Index

| NO. | ITEM | UNIT | INDEX VALUE | |

| 01 | Density | g/cm³ | 1.8-2.0 | |

| 02 | Water absorption | % | <0.5 | |

| 03 | Vertical bending strength | MPa | ≥350 | |

| 04 | Parallel impact strength(Charpy type) | KJ/m² | ≥33 | |

| 05 | Parallel shear strength | MPa | ≥30 | |

| 06 | Tensile strength | MPa | ≥240 | |

| 07 | Vertical electric strength(in oil of 90℃±2℃) | 1mm | MV/m | ≥14.2 |

| 2mm | ||||

| ≥11.8 | ||||

| 3mm | ||||

| ≥10.2 | ||||

| 08 | Parallel breakdown voltage(in oil of 90℃±2℃) | KV | ≥35 | |

| 09 | Relative dielectric constant(50Hz) | - | ≤5.5 | |

| 10 | Dielectric dissipation factor(50Hz) | - | ≤0.04 | |

| 11 | Insulation resistance after soaking(After soaking for 24 hours) | MΩ | ≥5.0×104 | |

| 12 | Fire resistance(UL94) | - | V-0 | |

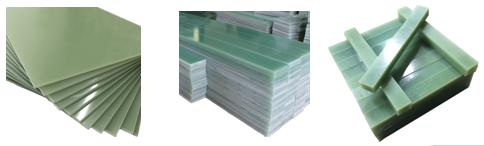

Product detail pictures:

Related Product Guide:

In order to give you convenience and enlarge our business, we also have inspectors in QC Team and assure you our best service and product for Manufacturing Companies for Fiber Glass Board - FR4 Rigid Epoxy Glassfiber Laminated Sheet – Xinxing, The product will supply to all over the world, such as: Jordan, UK, Wellington, Relying on superior quality and excellent post-sales, our products sell well in America, Europe, the Middle East and South Africa. We are also the appointed OEM factory for several worlds' famous products brands. Welcome to contact us for further negotiation and cooperation.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.